Everyone on this planet is urging to take steps towards a greener planet and this can only be done by laying the main emphasis on controlling pollution and packaging materials. Saying goodbye to plastic packaging and welcoming paper and kraft window boxes will definitely help in achieving it all.

Developing green advancements and reusing endeavors offer numerous decisions on the eco-bundling front. Anything produced using a substance created starting from the earliest stage like a true blue, naturally agreeable alternative.

Eco-packaging in a nutshell:

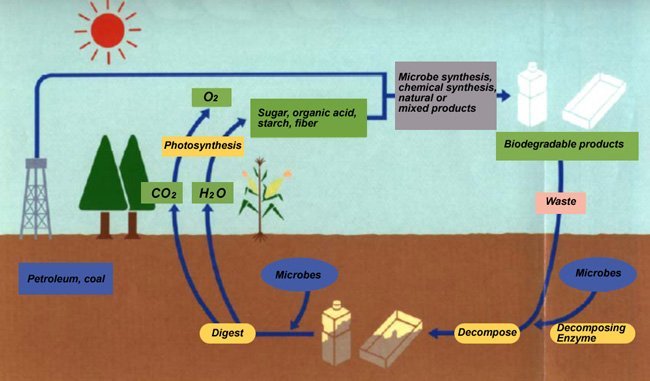

Eco-friendly packaging made of cardboard is a mix of rising green advances, and in addition utilizing recyclable materials. An emphasis on utilizing inexhaustible assets, which we will order as eco-plastics, mean to help plastics deteriorate speedier or be consumed into the indigenous habitat.

Meanwhile, advertisers have created cunning popular expressions, befuddling terms, and expressions to get Eco-kraft window boxes into our hands. Words like biodegradable, compostable, and recyclable are frequently utilized conversely, however they are not a similar thing. these words are maybe the way to understanding the difficulties of eco-bundling. we’ll investigate these thoughts later in the post.

The three regions of Eco-friendly packaging fall into these general classes:

- bioplastics: uses characteristic, inexhaustible materials and completely deteriorates. produced using pla (plant-based; corn or sugar) or from cellulose (wood, cotton, or hemp strands).

- biodegradable plastics: uses a blend of plants and petrochemicals and may completely biodegrade. A Few Kraft Packaging boxes highlight pha (polymers that create microscopic organisms) or psm (starch and polypropylene.) also known as photodegradable or oxy degradable.

- recyclable plastics: uses existing reused material to make new kraft window boxes. made with non-renewable oil based plastic. new on the scene is an eco-plastic called bio-polyethylene or inexhaustible bio-polyethylene, otherwise called bio-pe or green pe, (produced using ethanol; matured starch or sugar); this is non-biodegradable, yet can be reused with customary polyethylenes (hdpe, ldpe, lldpe).

Eco-kraft window boxes are always advancing, however, their improvement is not without faultfinders. for instance, some question the measure of vitality or assets utilized as a part of creating option plastics, similar to the utilization of land for developing corn, for instance. while the objective of a vanishing plastic appears inside achieve utilizing a compostable material, this too has its offer of difficulties. in general, these boxes have numerous natural advantages, yet the fact of the matter is in the points of interest. in all actuality, eco-bundling is dubious.

How to know everything about the material of the custom kraft window boxes?

The main way a buyer can know whether about the clear window boxes or paper window boxes is genuinely biodegradable or compostable is whether it meets the prerequisites of the american society of testing and measurements (astm). the astm d6868 and astm d6400 tests confirmed that compostable kraft window boxes and compostable plastics ought to have the capacity to completely corrupt inside 180 days.

Biodegradable:

All plastic is biodegradable, in the long run. indeed, even oil based packaging boxes will debase after some time under the correct conditions. considering that the main plastic was created by Leo Hendrik baekeland in 1907, it hasn’t been on the planet sufficiently long to know precisely to what extent it will stick around. all plastics aren’t equivalent either. a few plastics could take somewhere in the range of 450 to 1000 years to corrupt, while others debase all the more rapidly. the formation of biodegradable kraft boxes endeavors to accelerate this procedure however much as could be expected.

The procedure of decay requires the correct temperature, stickiness, and the nearness of microorganisms that separate the material and utilize it as a sustenance source. sounds like an impeccable get together of material and bugs.

Actually, if certain natural conditions aren’t right, deterioration is not liable to happen. at the end of the day, where this sack winds up decides if it will decay, regardless of the possibility that it’s thought to be biodegradable. In the event that it doesn’t crumble, it will rather separate into small pieces and abandon metal deposit or poisons in nature. this can make more damage to the earth than great.

Certain conditions must be set up for a biodegradable pack to break down. since landfills are bereft of daylight, dampness, and oxygen, biodegradable packs can’t break down in this condition. This sans oxygen condition produces methane, which is an ozone depleting substance 20 times more intense than CO2. the landfill is obviously not the place for a biodegradable pack.

Be that as it may, the circumstance is not outlandish. biodegradable kraft window boxes can help the earth when they are discarded appropriately. should you pick this course, maybe one thing to consider is the means by which to instruct your clients in legitimate transfer so the eco-advantage of this item is not lost.

Compostable:

A biodegradable item isn’t really compostable; however eco-friendly kraft packaging boxes are to be sure biodegradable. for an item to be compostable it must biodegrade, deteriorate, and have no eco-lethality. not at all like biodegradable craft window boxes, compostable kraft window boxes separate into “humus” which gives supplements to the dirts and does not discharge metals or poisons.

Bioplastic kraft boxes are either produced using inexhaustible assets like sugar or corn, or are cellulose-based and produced using wood, cotton, or hemp filaments. Plant-based kraft window boxes are produced using polylactic acid (pla) that is gotten from cornstarch or sugarcane. with the second biggest generation volume of any bioplastic, it is a mainstream decision. pla is said to deteriorate into carbon dioxide and water in less than 90 days in a controlled treating the soil office. another advantage is that pla can be separated and made into crisp pla.

Cellophane is a plastic that is produced using a natural compound called cellulose. these eco-friendly kraft boxes are not to be mistaken for famously named “cello” packs which utilize polypropylene plastic. cello sacks begun with celluloid packs (not cellulose) and inevitably turned into an industry standard term. the eco-accommodating cellulose-based kraft packaging boxes are gotten from wood, cotton, eucalyptus mash, and hemp strands.

Recyclable!

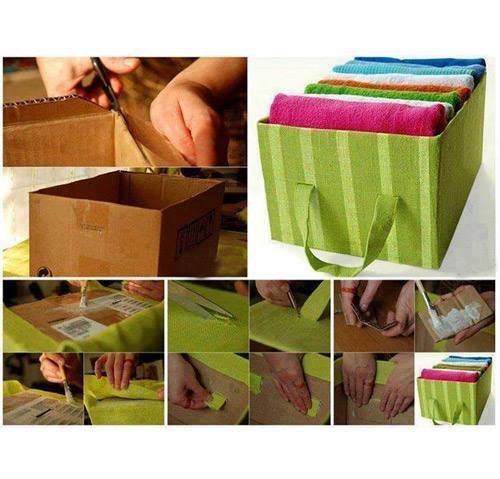

At long last, there are custom window boxes produced using reused materials and boxes that can be reused.

Ordinarily, an item is named as recyclable when it can be gathered, isolated, or recuperated from the waste stream so it can be reused or made into another thing.